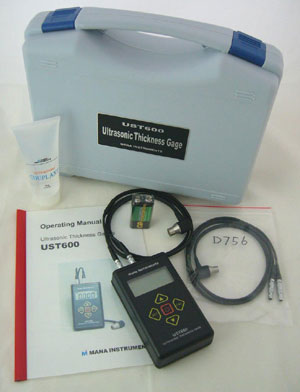

UST600

High Performance Ultrasonic thickness gauge

The UST600 ultrasonic thickness gauge. Handy. Pocket sized. Digital display with integrated check of the function of the gauge for operational readiness, continuously indicates battery status, condition of the coupling. exceeding the measuring range. High display stability by means of “averaging”. Differential mode displays the difference between measured thickness and user-set nominal thickness value. Programmable HI/LOW thickness limits with beeper alarm. The sound velocities can be pre-programmed. It will be logged in memory until changed. Measured values and user information are shown on a large, easy–to–read LC display. A display back light (optional) ensures easy reading of screen data, in poorly-lit conditions.

With uses in many areas of industry the UST600 can perform precise measurements of various types of raw materials, component parts, and assembled machinery. It is especially applicable to the measurement of remaining wall thickness on tubes, pipes, pressure vessels, and other parts subject to wall thickness loss due to corrosion or erosion.

Employs the ultrasonic pulse-echo method with dual element transducer. Can be used on flat and curved materials.

Very easy to operate. Switches itself off automatically. Due to the possibility of the zero point correction and the sound velocity programming extended sound path flaws and/or flank flaws in the near and/or the far range can be localized within tight tolerance limits. |